0086-576-83230902

This solution applies to intelligent bridge and gantry cranes such as fully automatic cranes, intelligent cranes, andunmanned cranes and is widely used in fields such as inteuigent manutacturine, nower plants, cement olants, steel milispapermaking,and biomass power generation.

This involves only transferring workpieces, goods, etc, to different locations, commonly used in intelligentmanufacturing workshops, cargo loading and unloading, and other occasions such as steel plate blanking, steel structuremanufacturing, plate blank rolling, and other manufacturing sites. lt mainly includes technologies such as intelligentlifting devices, positioning and anti-swing systems, path planning and obstacle avoidance, video monitoring systems, andautomatic control systems. Some engineering cases also include wireless transmission systems and automatic faultdiagnosis systems.

As a lifting tool, the bucket grab operates in material sheds, storage yards, and raw material warehouses for storingand transporting bulk materials such as sand, coal, cement, garbage, and loose straw, in places where scrap steel ishandled by grabs r electromagnetic disks, intelligent crane technology is applied for workstation transfer, Additionally.material level detection systems, grab attitude monitoring, and automatic landing systems are installed, Some projectcases also include weighing and reporting management systems, as well as multi-devicescheduling systems.

For automated storage and transportation in warehouses and distribution centers for bulk materials such as steecoils, profiles, paper rolls, and straw bales, in addition to the aforementioned technologies, it also includes inventorymanagement, equipment scheduling, monitoring systems, etc, its characteristics include a more complex system, moreoperating equipment, closer connection between inbound and outbound processes, as well as memory storage, reportmanagement,etc.

Operation Modes: Manual Control, Remote Control, Remote +Intelligent Control

Control Mode:PLC+ FrequencyConverter+ Touch Screen+ Remote Control Console

The entire machine can achieve unmanned operation: automaticgrabbing,stacking, dumping, loading and unloadingas well as warehouse management functions, The degree of automation is high, and the performance is superior.

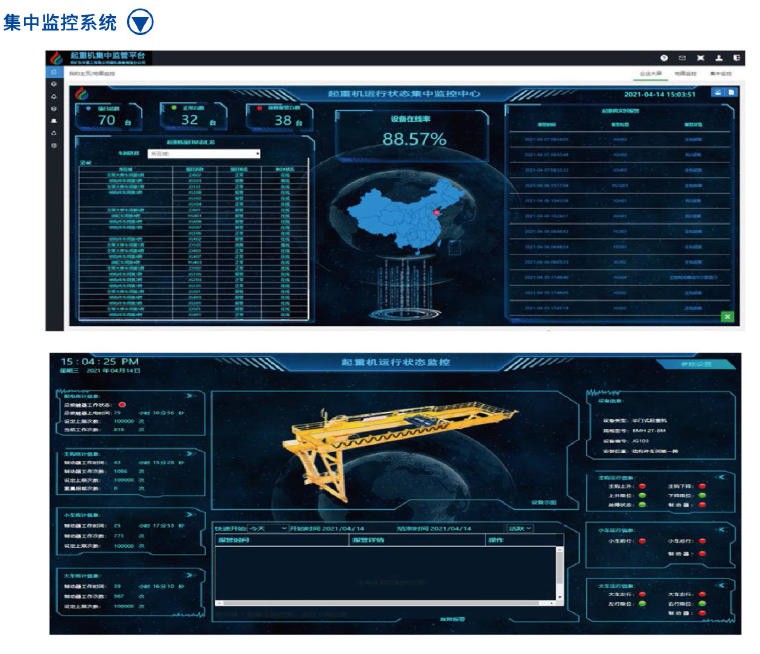

Hardware Configuration: PLC+ Frequency Converter Control System, 3D Positioning System, Wireless CommunicationNetwork,intelligent Spreader Control, Safety Protection System, Remote Monitoring System

Main Functions:

1.Warehouse Management

2.3D Intelligent Recognition

3.Inventory Calculation

4.Digital Twin Svstem

5.Video Tracking System

6.Vehicle Recognition

7.AutomatedLoading/Unloading Function

8.EquipmentManagement Function

Scan the QR code

Scan the QR code